Process Vessels

Here are the main vessel types in our grease plant projects.

On smaller plants, we normally use a single stage process, based on kettle to do both the saponification and the finishing.

For larger plants we normally use a two stage process. The first stage is saponifying in an autoclave or saponification kettle. The second stages is finishing in kettles where the dilution base oils and additives are introduced.

Our process vessels are built by UK manufacturers who work as our subcontractors to our designs. If the circumstances demand we can outsource from other countries, depending up the quality and reliability of the company concerned.

Saponification

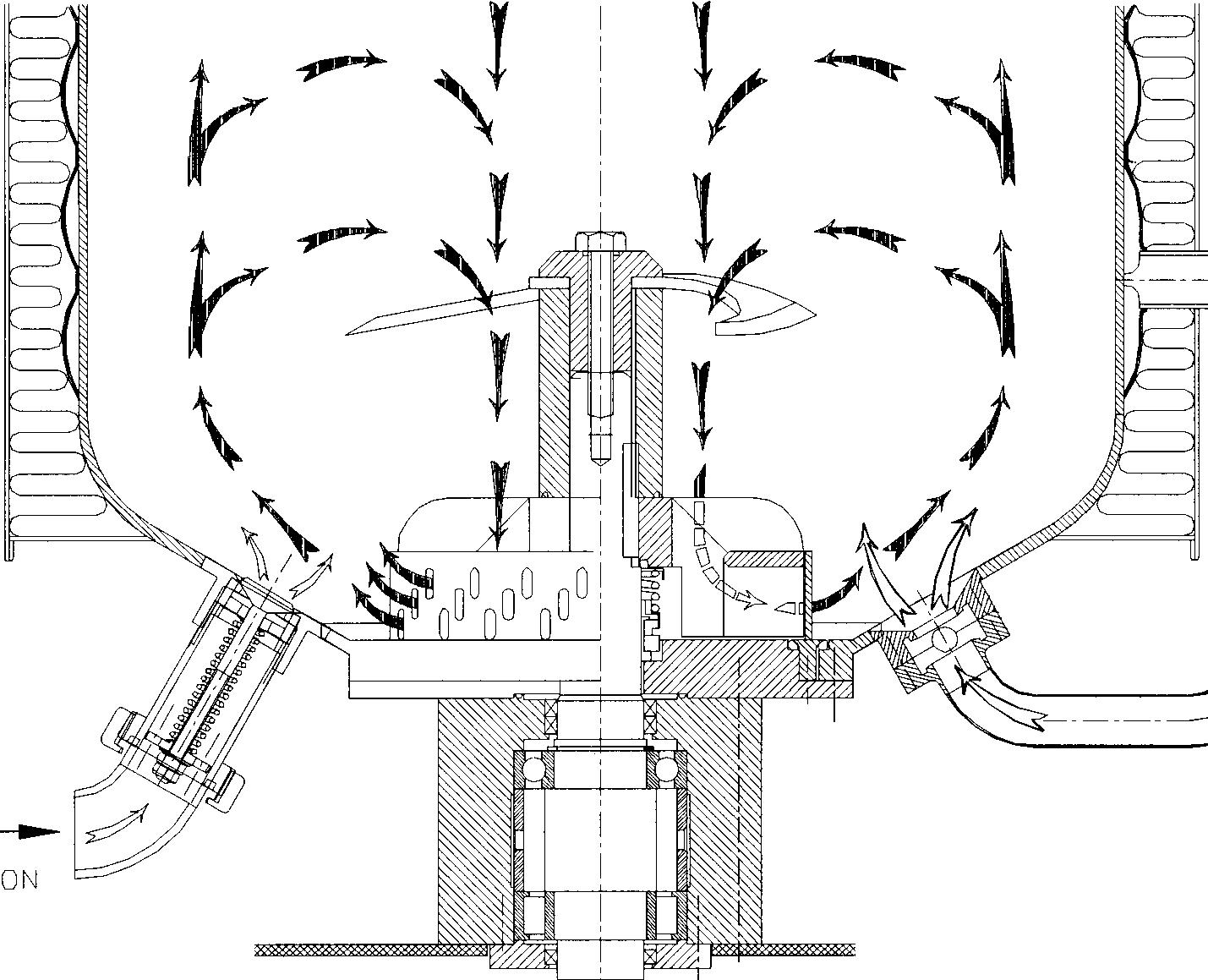

This is a contra-rotating jacketed vessel, optimised for saponification and complexing reactions. It features:

- Contra-rotating vessel with higher powered agitation on the inner paddle to increase the reaction rate and completion

- Pressurised build option that benefits mono-soap formation

- Jacket zoning option for half-sized batches

- Variable speed inverter drives are used to allow the agitation to be slowed down for more shear sensitive products.

If required, we can source grease contactors, which have an internal jacket to speed up the heating rate. This is potentially better for high volume manufacture of a small number of grease types, but the internal jacket’s annular space can block up when making high drop point greases.

Finishing

Finishing is the next stage from saponification or complexing. The Finishing kettle is a jacketed contra-rotating vessel with the following features:

- Agitation with a slow speed outer gate and an incoporator with a higher RPM and power

- Variable speed drives

- Optional jacket double-zoning for smaller batches

If the need arises, our finishing kettles can also make the entire grease batch, from saponification or complexing to finishing.

Bottom End Dispersion and Turbo Mixing

A bottom mounted dispersion unit can potentially make complex grease more effectively because it prevents the build up of partly reacted soap at the bottom of the batch.

We have supplied a turbo mixer (high power bottom entry turbine plus gate) and on another occasion, a contra-rotating system with an additional blade at the bottom for this purpose. An even better option is a triple motion system which uses a low speed gate or anchor, medium speed inner agitator and high speed bottom agitator.

We can also offer a turbo mixer for high speed dispersion of solids in grease and for gelling oils/fluids with thickeners such as silica. The advantage of the high speed dispersion is that more batches can be made in one day.